Titanium &Titanium alloy Flange

1.Quick Details

| Product name | Titanium & titanium alloy Flange |

| Standard | ASTM 381, AS ME/ANSI B 16.5, DIN 2630-2633, BS etc |

| Size | ANSI 1/2"-80" |

| Thickness | SCH 20, SCH 30, SCH 40, STD, SCH 80, SCH 100, SCH 120, SCH 160, XS |

| Material | TA 1-TA 4, TA 8-TA 10, TA 15-TA 18, GR 1-GR 5, GR 7, GR 9, GR 11, GR 12, TI-6AL-4V, T-6AL-4VEL,Zirconium etc |

| Pressure rating | 0.6~32Mpa |

| (DIN) PN 6, PN 10, PN 16, PN25thoughPN 250 | |

| (AS NI) CL 150, CL 300, CL 600, CL 900, CL 1500 | |

| Working temperature | -60°C-250°C |

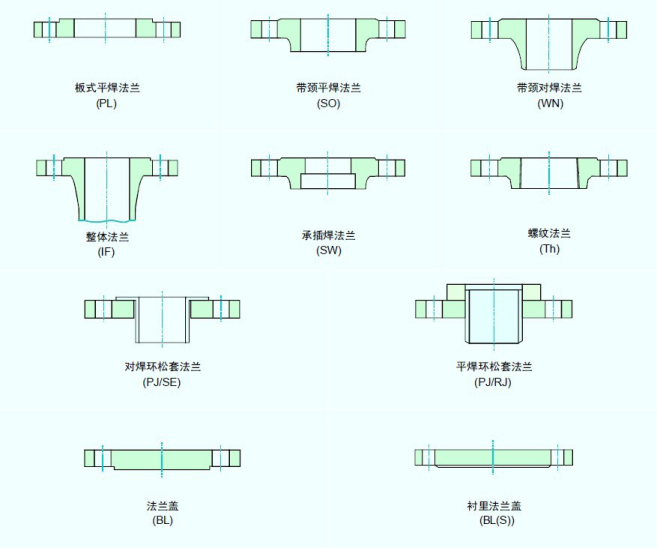

| Type | Plate, threaded, slip-on, socket welding, lap joint, blind, welding neck, reducing, blind |

| Flange face | FF.RF.TG, RJ etc |

| Quality control | Ultrasonic Testing&Material Test Report |

| Application | 1.Chemical industry, Chemical processing including polymer production |

| 2.Pulp and paper production | |

| 3.Marine engineering | |

| 4.Oi and gas offshore drilling rigs | |

| 5.Machining field, Automobile field, etc. | |

| 6.Textile printing and dyeing | |

| 7.Mobilephone component field |

2.Introduction of flange

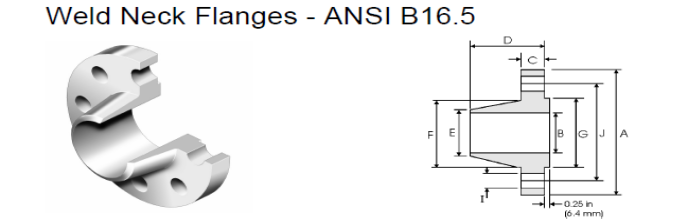

1)Weld neck flanges

The weld flange is the standard against which all other ANSI flanges are measured when it comes to strength and wear life. Long weld neck flanges are the standard because they are used for many different high-pressure applications at a variety of extreme temperatures and are designed to limit turbulence and erosion at the joint.

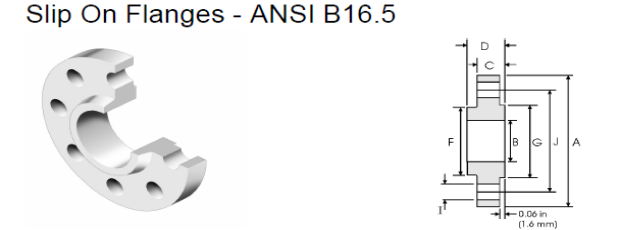

2)Slip-On Flanges

In general, these flanges are rated at about two-thirds of the strength of a standard long weld neck flange and they have a fatigue life of about one-third of that of a comparable long-weld neck flange. They are connected to pipes using two filet welds, one at the outside of the flange and another at the inside of the flange. This makes them a bit more time consuming to install on a pipe, as well as reduces the versatility of the flange because combining them with elbow and tees is not possible. All fittings used with slip-on flanges must have a straight end.

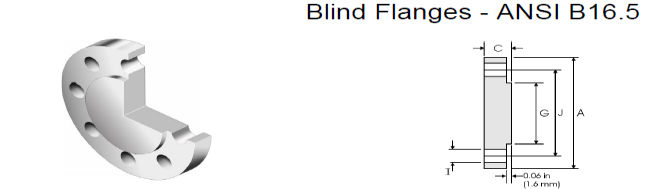

3)Blind Flanges

Blind pipe flanges seal off pipes, valves, and ASME pressure vessel openings while providing an option to expand the pipeline network in the future. These flanges are also often used for high-pressure testing within the pipeline network.

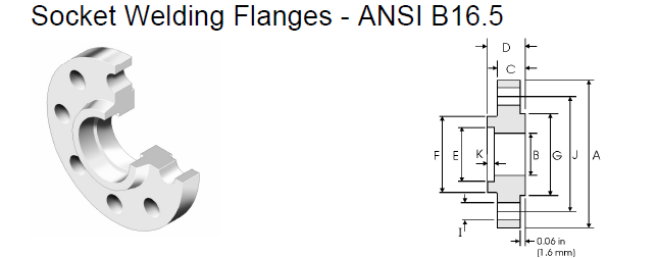

4)Socket Weld Flanges

Socket weld flanges are just about as strong as slip on flanges, but are about 50% stronger when it comes to resisting fatigue. These flanges are attached using a single fillet weld on the outside of the flange. This makes them less labor intensive to install.

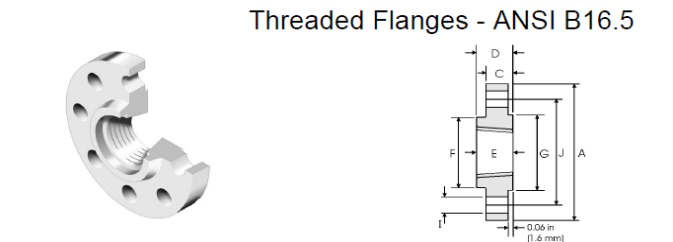

5)Threaded Flanges

The best thing about threaded flanges is that they can be installed into a pipe system without welding. These are used for smaller pipe sizes most of the time and only for pipe systems that have thick walls.

Type of thesueface